15358968703

Efficient intelligent monitoring and digitalization technology for continuous casting

2026-02-04

1. Research Background Continuous casting is the core process that links steelmaking and steel rolling. Its stability and intelligence level directly affect product quality, production efficiency, and equipment safety...

The reasons why the bearings of steel mill rolling machines are prone to damage and the solutions for addressing the problem

2026-02-04

High load and complex conditions Extreme load shock The rolling mill bearings have to withstand 2 to 5 times the radial load of ordinary bearings. Moreover, they are affected by various working conditions su...

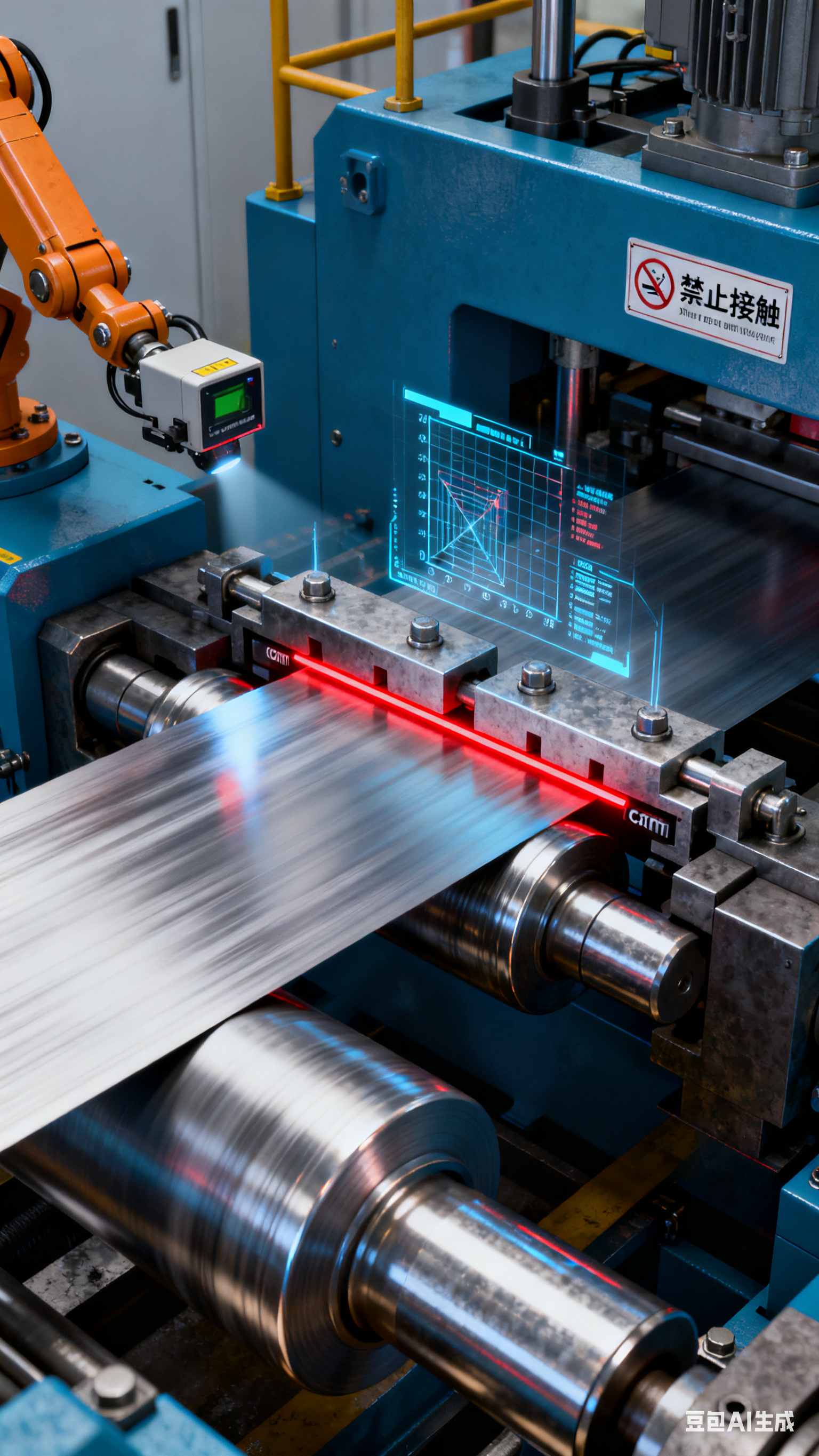

Research and development of integrated short-process casting and rolling technology and equipment

2026-02-04

1. Research Background and Overall Task Objectives The steel industry, as a typical process industry, has complex production processes involving multiple stages and a long production line. During the development and p...

A comprehensive description of 16 common defects in rolled steel billets

2026-01-19

A comprehensive description of 16 common defects in rolled steel billets The billets used by cold-rolling strip steel mills are hot-rolled strip steel. The poor quality of the billets themselves and incorrect pro...

Research and development of integrated short-process casting and rolling technology and equipment

2026-01-19

1. Research Background and Overall Task Objectives The steel industry, as a typical process industry, has complex production processes involving multiple stages and a long production line. During the development and p...

Thermal treatment mechanical property indicators and testing methods

2025-12-17

The mechanical properties of metallic materials mainly include strength and plasticity, hardness, impact toughness and fatigue strength. The strength index of the mechanical property test of metallic materials can better help u...

Tips for "All-staff preventive Maintenance Centered on inspection"

2025-12-17

The bearings of the rolling mill are in operation Perhaps for various reasons This leads to premature damage of the bearing Even under normal installation, lubrication and maintenance conditions After a period o...

Research Progress and Prospect of Ultra-High Strength Steel

2025-12-17

Abstract: Ultra-high strength steel is the core material for key load-bearing components of major equipment such as aerospace and construction machinery. This article reviews the current technological status of ultra-high stren...

Summary of knowledge about metal brittleness

2025-11-10

Metal is everywhere in our daily life and engineering construction: from Bridges and high-speed railways to aircraft and automobiles, metal is a key material. But do you know? These seemingly solid metals can sometimes be "...

Common defects of pickled coils and their solutions

2025-11-10

I. Defects of Pickled Plates 1.1 Raw Material Defects 1.1.1 The roll diameter of the raw material is inappropriate and too small. Especially for thin-sized hot-rolled coils. Mainly d...

What temperatures do TB RT, RDT, TIT, FDT and CT respectively represent in hot continuous rolling?

2025-11-10

TB (Billet Temperature Representing the temperature of the billet, it refers to the temperature of the slab before it enters the heating furnace. This temperature mainly depends on the source of the billet and th...

A Comprehensive Analysis of the Identification and Testing of Cold-rolled Steel and Hot-rolled Steel: In-depth Analysis from Principles to Methods

2025-10-15

In the field of metallic materials, cold-rolled steel and hot-rolled steel are two common forms of steel. Due to the differences in their production processes, they have significant distinctions in performance, appearance and a...